A scissor lift is a machine made to move personnel and equipment in a vertical direction. These lifts can handle any application that would normally require a ladder, tower or scaffolding. Scissor lifts enable operators to complete the same jobs faster and more securely without the setup time of other equipment, such as scaffolding or a tower, and without the dangerous instability of a ladder.

Our evevators tables can be pit installed or floor mounted, sited indoors or outdoors. Whether your requirement is within the warehouse, loading bay, production line, packing area – whatever your application and industry, there is our lift table to solve your materials handling problem.

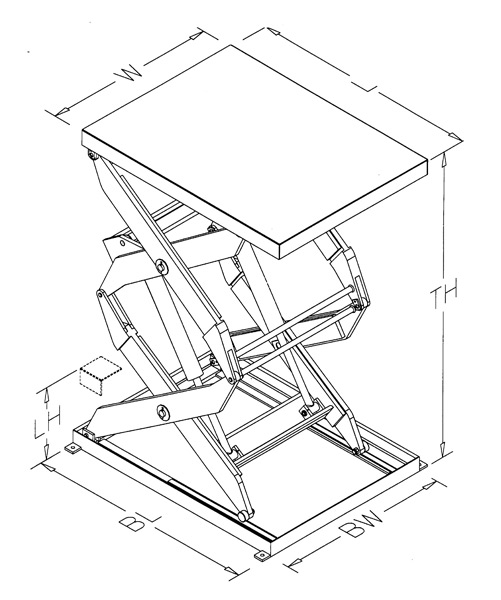

Scissor Lift Mechanism

A scissor elevator is a very common aerial lift nowadays because of its many advantages. It minimizes risk, is easy to operate, and can carry heavy loads. It is available in many different sizes, and requires minimal storage space. It employs a very simple mechanism that we are going to look into below.

It use simple parts to provide an efficient and quick work platform at a height.

- Platform

This is the space on which personnel and/or merchandise are positioned. - Base

This is the foundation on which the machinery rests. - Scissor Legs

These are the parts that allow the lift to ascend and descend. - Hydraulic cylinder

This is what lets the scissor legs move. One to three cylinders are positioned between the scissor legs. - Motor

This gives the machinery all the energy it needs to get raised or lowered.

To raise the platform, fluid is pushed into the cylinder. A control valve manages the level of fluid to help the platform maintain its height. When the fluid is released from the cylinder, the platform is lowered. To allow for a safe descent, fluid is released carefully, and its speed is managed by a control valve.

Types of Scissor Lifts

1. Hydraulic Scissor Lift

Hydraulic scissor lift is a popular option. The only problem, however, is that the hydraulic oil in the cylinder is affected by temperature. This means that in warmer conditions, the machinery operates at a faster speed as compared to in cold conditions. However, this problem normally occurs in old models of hydraulic lifts.

2. Electrical Scissor Lift

Electrical scissor lifts are an ideal option for indoor projects although they can be used for outdoors as well. They use electricity from a direct power source or battery. They are quiet, and produce zero emissions. It is extremely portable due to its compact size and innovative controls. Diesel scissor lifts use diesel to operate, which causes emissions. These are intended for outdoor use, and can be extended between 10 and 18 meters from the ground.

Uses of Scissor Lifts

Scissor lifts are used in a variety of projects. Some of them are mentioned below.

- Building maintenance

They are very useful when performing tasks such as changing light bulbs, changing or hanging signs, and hanging posters or banner. - In Industries

The scissor lifts can often be seen performing various tasks related to loading.

- Retail

The shelves in a warehouse are quite tall which are much easier to reach with the help of a lift. - Fire

In case of a fire, scissor lifts present an easy and safe way to access tall parts of a building and attempt rescue missions.